Peeled And Ground Bars

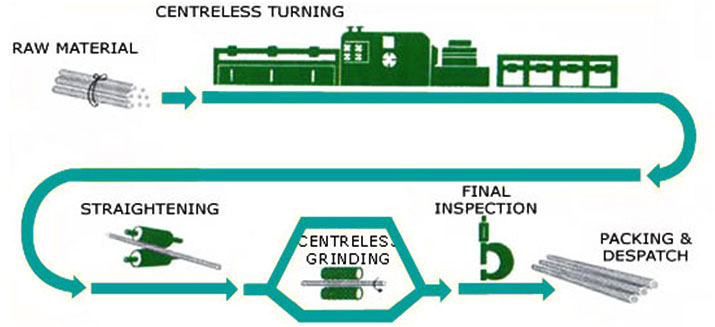

Peeled and ground Bars are made from Hot Rolled Bars through the process of Pre straightening, Peeling, reeling and Centreless Grinding. It gives greater dimensional accuracy, straightness, smooth surface, free from surface defects and enhanced mechanical properties to the product.

Peeled and ground bars are manufactured in a variety of sizes, according to various specifications of steel, and conforming to BSS, EN series, SAE, ISI, DIN, AISI, which signifies reliability and quality that the company focuses on.